Hello! Welcome to Dongguan Hongbao Electromechanical Technology Co., Ltd. Official website!

+86-138-2924-2619

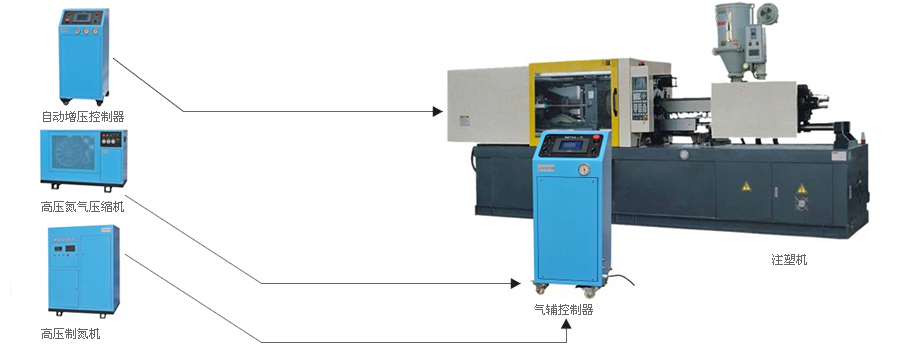

Gas-assisted injection molding technology has been applied in China for more than ten years. Its principle is to use high-pressure nitrogen gas injected into the interior of plastic products, so that hollow sections are produced inside the plastic products. High-pressure nitrogen is used instead of injection molding machine for high-pressure injection and its holding pressure. The internal pressure of the plastic product is pressed to the outside, and the surface of the plastic product is close to the surface of the mold, the plastic product sink marks and the internal stress of the plastic product are eliminated, and the entire injection process is completed. The gas assisted injection molding process mainly includes a plastic filling stage and a switching delay stage. The gas injection stage, the hold pressure stage, the gas release stage, and the ejection of the six stages. According to the different injection volume, can be divided into short shot (short shot injection) and full shot two ways, short shot gas first push the melt full type Cavity, and then maintain pressure; in full-fire mode, the gas only plays the role of pressure preservation, according to different ways of intake can be divided into four types, 1 nozzle intake, 2 flow inlet, 3 product internal intake, 4 Product surface intake

Solve the problem of surface sink marks and improve the surface quality of products

Reduce product weight (up to 20%-40%) and save raw materials.

Reducing the injection pressure reduces the pressure in the cavity and extends the life of the mold.

Reducing clamping pressure is not a high pressure injection molding machine can achieve power-saving effect

Due to thicker ribs in plastic products, hollow plastic piles are plastic products cooling time

Shortening, shortening the molding cycle of products and improving production efficiency.

Simplifies mold design and gating system, reducing mold costs.

Reduce internal stress, reduce warpage and increase product strength.

Improve the molecular structure of plastic materials and improve the rigidity of products.

Follow us

Mobile station